March 6, 2024

Managing Dust for Enhanced Electronics Reliability in Mining Operations

Managing Dust for Enhanced Electronics Reliability in Mining Operations

Dust and MTBF: Enhancing Electronics Reliability

In the realm of electronics, the presence of dust within electrical cabinets poses a multifaceted challenge. While dust may lead to shorts, depending on its composition, it also acts as an insulating layer, hindering proper cooling of electrical components. As we understand, the Mean Time Between Failure (MTBF) exhibits a strong correlation with the operating temperatures of electronics, characterized by an exponential relationship. Thus, ensuring dust-free environments that facilitate adequate cooling significantly bolsters the reliability of electronic components. This realization has prompted mining companies to adopt stringent cleaning procedures for critical electronics cabinets.

Cleaning Procedures and RCS: A Safety Concern

Pressurized air stands as the primary tool for periodically clearing dust from electrical cabinets. However, a substantial portion of this dust comprises Respirable Crystalline Silica (RCS), presenting a significant safety hazard for individuals conducting the cleaning. Exposure to RCS can contribute to severe ailments such as silicosis and lung cancer. Alarmingly, in 2017, the Queensland Mines Inspectorate reported that around 50% of all respirable dust and RCS exceedances observed in surface coal mines stemmed directly from compressed air usage during maintenance activities. Notably, a third of these exceedances specifically related to blowing out high voltage cabinets in electric drive trucks or motor-generator sets in dragline houses.

Prevention Over Remediation

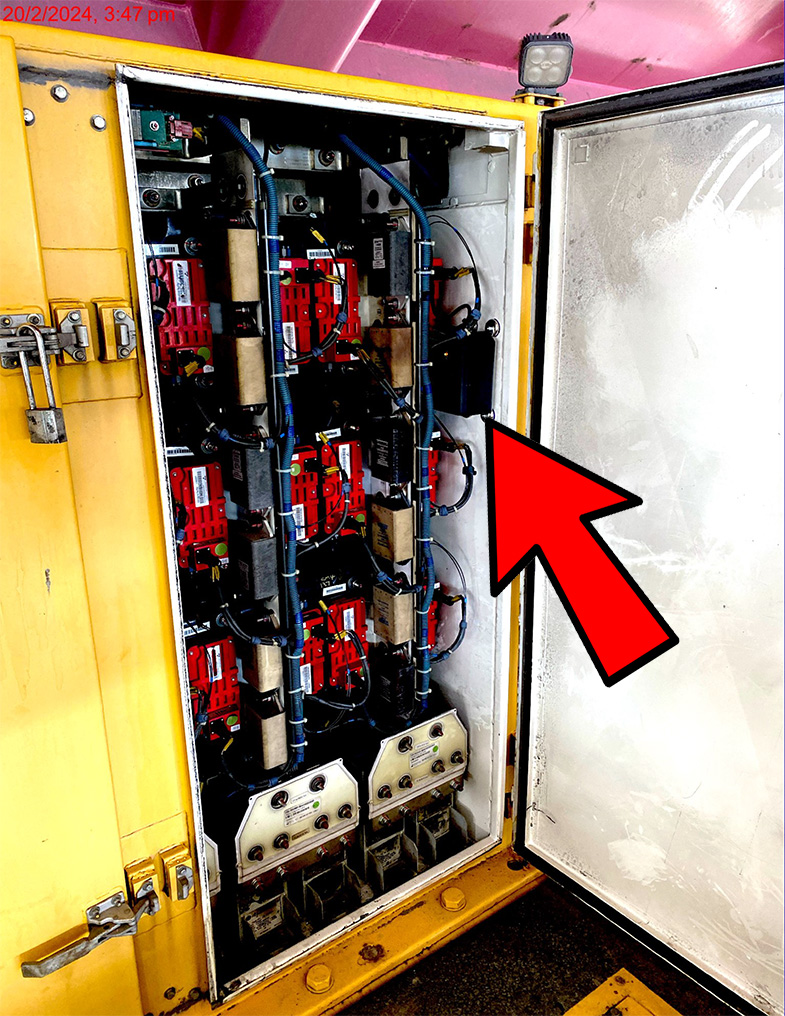

Given the hazardous nature of cleaning operations, it becomes imperative to prevent dust intrusion into electrical cabinets altogether. This approach not only minimizes the need for risky cleaning procedures but also promotes a safer work environment. To support this preventive stance, CabSafe has collaborated with a mine operator in Australia to install CabSafe units inside the main electrical cabinets of Komatsu mining trucks. These installations serve as the baseline for quantifying the effectiveness of future improvements.

CabSafe Installation and Data Analytics

CabSafe operates as a fully self-contained air-analytics lab, requiring either 10-30VDC or a USB battery bank for operation. Data retrieval occurs via LTE-M or through a mobile phone, facilitating seamless offloading to the analytics portal. Its self-contained design allows for flexible deployment, enabling detailed air-quality assessments within driver cabins or electrical cabinets.

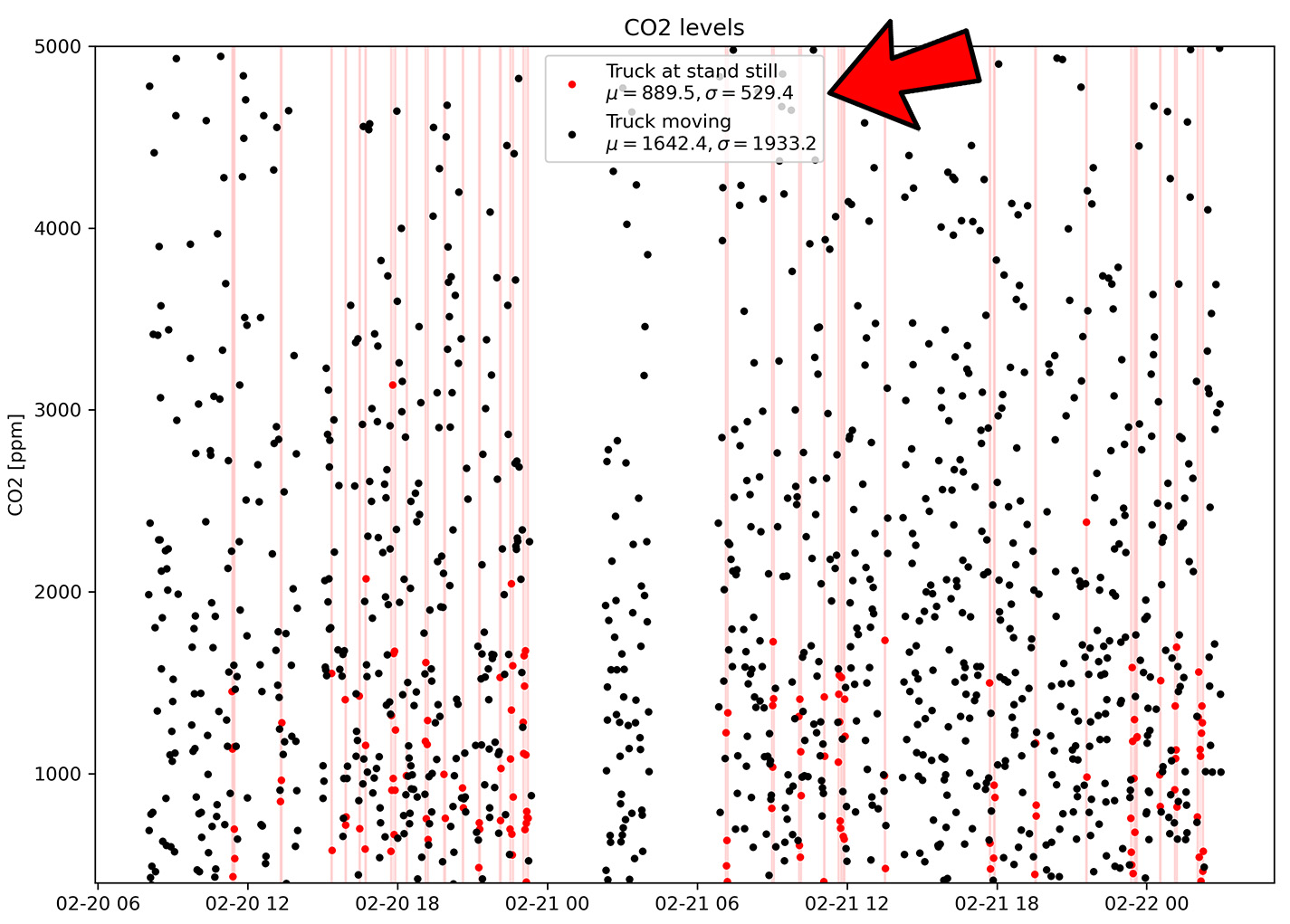

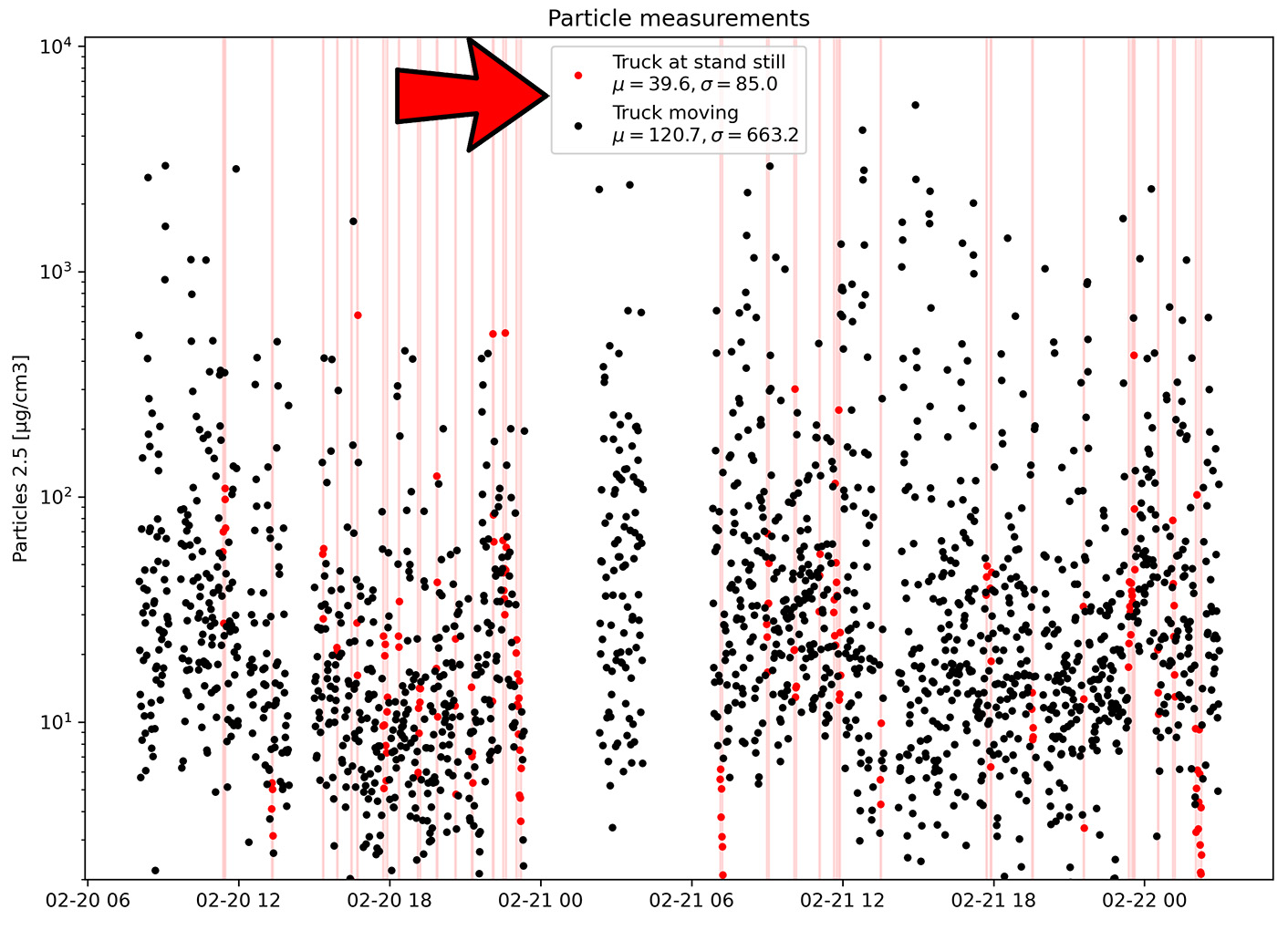

Measurement Insights

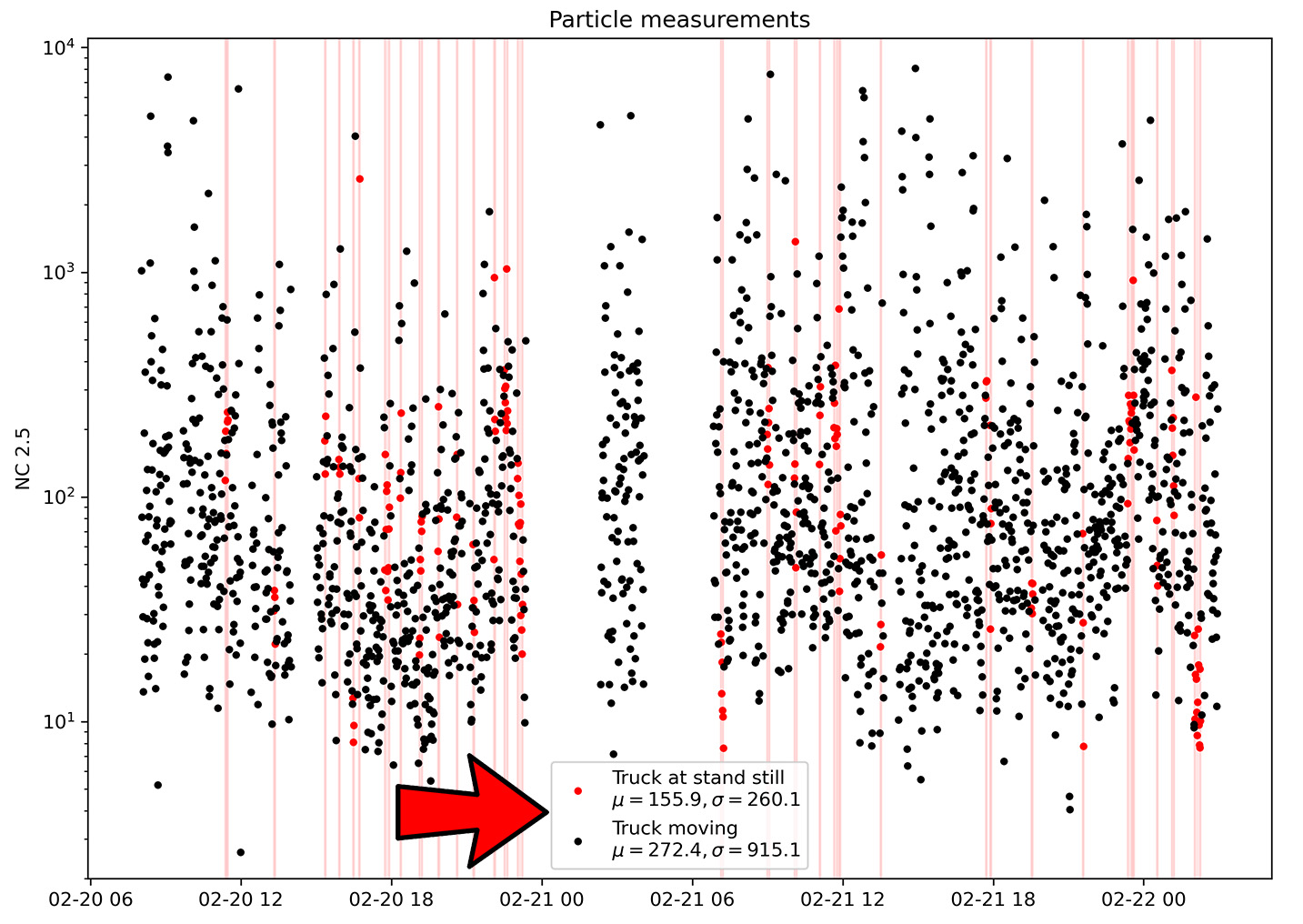

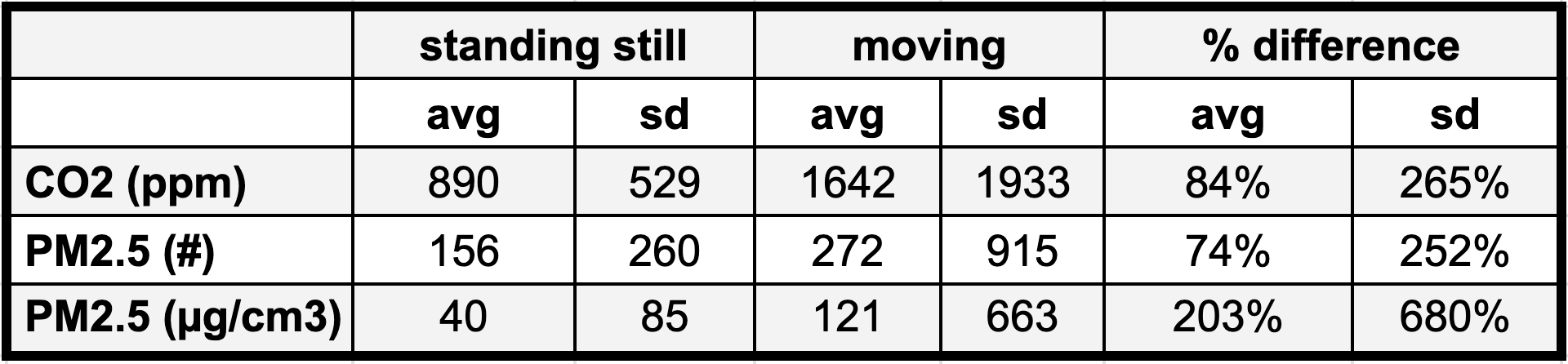

CabSafe’s built-in accelerometer enables the distinction between the truck’s stationary and driving states. Each graph provides averages and standard deviations for both datasets, highlighting notable differences in CO2 readings and particle concentrations between stationary and mobile states. Baseline readings underscore substantial room for improvement. Following enhancements to the air-cooling systems within these cabinets, we anticipate quantifiable improvements, which will be documented in future measurement campaigns.

Stay tuned for updates on our ongoing efforts to optimize the cooling of this Komatsu truck electrical cabinet!