Why CabSafe?

Increasing awareness of the risks created by dusty industrial environments to human operators and operations

Safer workplace

Optical Sensing

Economical

CabSafe is crucial for fleet operators aiming for ISO 23875 compliance

ISO 23875 is a new international standard that unifies the design, testing, operation, and maintenance of air quality control systems for heavy machinery cabs and other operator enclosures, particularly in the mining industry. Adhering to ISO 23875 means embracing globally recognized practices, enhancing safety for operators in the demanding mining industry.

Setting the Standard:

CabSafe's Revolutionary Approach

Today, a majority of mining-truck cabins lack monitoring, leaving a safety gap. Even with monitoring, the focus is often limited to Carbon Dioxide (CO2), neglecting particulate matter and air filtration effectiveness. The absence of a standardised, fleet-independent solution hinders data consistency and informed decision-making. CabSafe emerges as the answer, providing a comprehensive and efficient solution for monitoring challenges in mining-truck cabins and across other applications where managing dust is a challenge.

Real-Time Monitoring

Comprehensive

Fully Configurable

Connectivity

High-Quality Data

Smart System

Environmental Impact

Navigating the Dust Dilemma: CabSafe's Innovative Solutions

Global dust issues, driven by factors like climate change and extreme weather, pose a rising concern. These conditions escalate dust generation, soil erosion, and airborne particulates, impacting health. Industries globally are prioritizing measures for worker and environmental protection. This trend has resulted in stricter legislative frameworks for dust control and monitoring. CabSafe, our solution, effectively tackles these challenges in industrial settings. Learn how CabSafe can safeguard your workforce and the environment.

Connectivity Driving Safety & Compliance

Experience heightened safety with CabSafe – where connectivity is paramount. Our innovative solution employs LED indicators on the product and a dedicated app on the driver's phone to instantly alert and record elevated particulate levels, ensuring a rapid response. Additionally, seamless connectivity empowers our system to record and report Cabin Air Quality to the HSE department, enabling proactive management of air quality across extensive mining vehicle fleets.

Android & iOS Support

Personal Alerts

Personal Recording

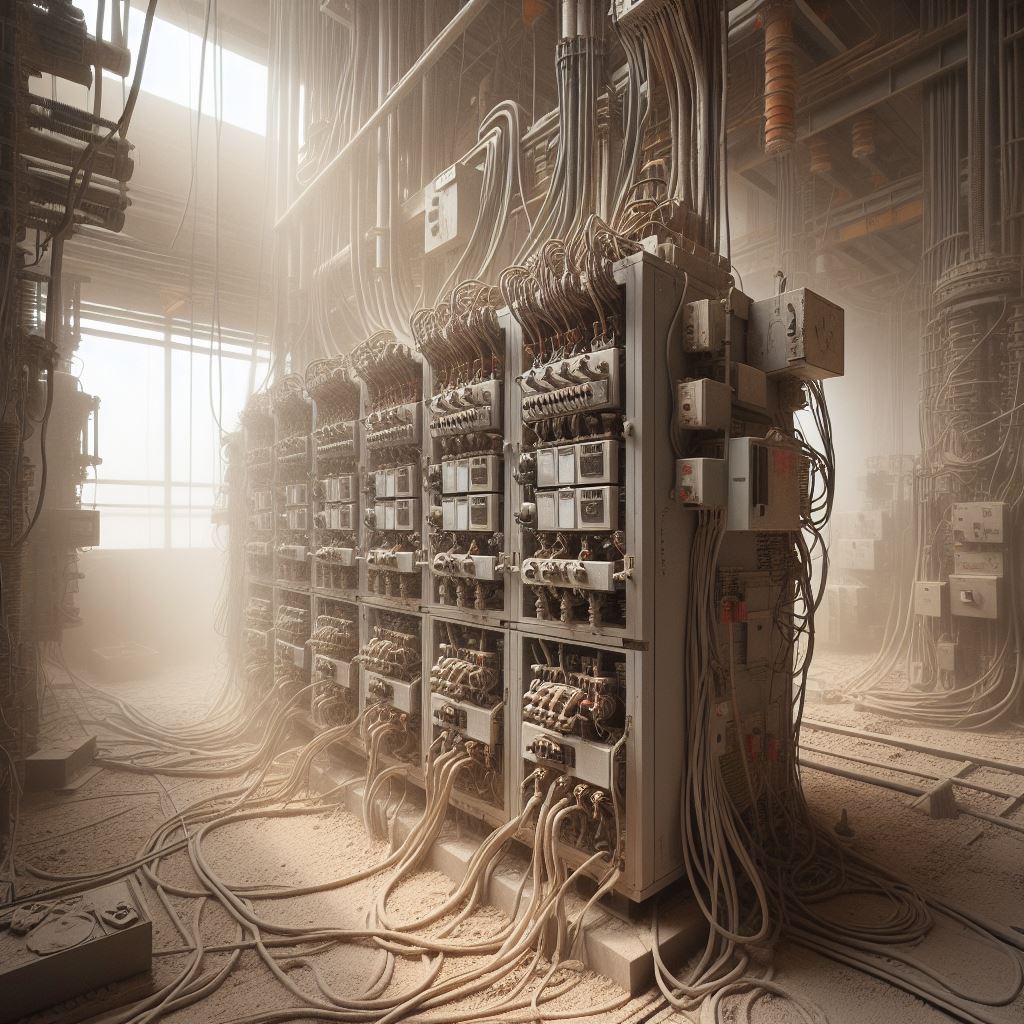

Revolutionize Electrical Switchgear Safety with CabSafe

Dust in electrical switchgear poses hazards like insulation breakdown and fire risk. CabSafe’s proactive solution monitors cabinet environments, swiftly detecting and alerting to dust accumulation. This enables prompt preventive maintenance, ensuring safety and efficiency in dusty conditions through real-time monitoring and adherence to safety standards.